What is an ALC Panel Machine and How Does It Work?

Autoclaved Lightweight Concrete (ALC) panel machines are specialized equipment designed to manufacture lightweight, precast building materials. These machines produce panels that combine structural strength with excellent insulation properties, making them ideal for modern construction projects.

The manufacturing process involves several key steps:

- Raw material preparation and mixing

- Casting and molding

- Autoclaving (high-pressure steam curing)

- Cutting to precise dimensions

- Quality control and packaging

ALC panel manufacturing equipment typically operates on a continuous production line, allowing for high-volume output with consistent quality. The panels produced by these machines offer numerous advantages over traditional construction materials, including faster installation times and better thermal performance.

Key Benefits of Using ALC Panel Machines

Superior Material Properties

ALC panels manufactured by these machines exhibit exceptional characteristics that make them stand out in the construction industry:

- Lightweight (about 1/4 the weight of concrete)

- High compressive strength

- Excellent thermal insulation

- Fire resistance up to 4 hours

- Sound insulation properties

Economic Advantages

When comparing ALC panels to traditional materials, the economic benefits become clear:

| Factor | ALC Panels | Traditional Brick |

|---|---|---|

| Construction Speed | 3-4 times faster | Standard pace |

| Labor Costs | Reduced by 30-40% | Higher requirements |

| Material Waste | Less than 5% | 10-15% typical |

How to choose the right ALC panel machine for your needs

Selecting the appropriate ALC panel production equipment requires careful consideration of several factors:

Production Capacity Requirements

The size of your operation will largely determine the type of machine you need:

- Small-scale operations (up to 50,000 m³/year)

- Medium-scale operations (50,000-150,000 m³/year)

- Large-scale industrial production (150,000+ m³/year)

Technical Specifications

Key technical aspects to evaluate include:

- Automation level (manual, semi-automatic, fully automatic)

- Energy consumption metrics

- Cutting precision capabilities

- Mold changing flexibility

ALC panel production line setup and configuration

Establishing a complete ALC panel manufacturing facility involves multiple components working in harmony:

Essential Components

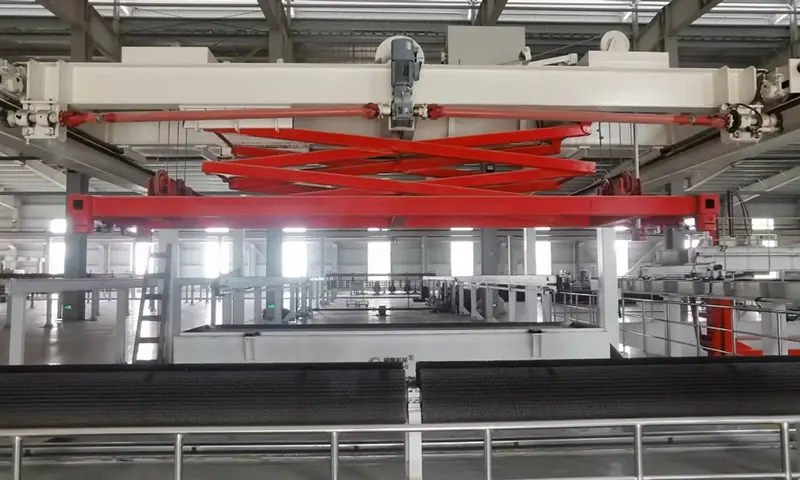

A typical production line consists of:

- Raw material storage and handling system

- Mixing and dosing equipment

- Casting and pre-curing stations

- Autoclave system

- Cutting and finishing machinery

Layout Considerations

Optimizing your production floor space requires careful planning:

| Area | Space Requirement | Key Functions |

|---|---|---|

| Raw Material Storage | 200-500 m² | Cement, lime, sand storage |

| Production Line | 800-1500 m² | Main manufacturing processes |

| Curing Area | 300-600 m² | Autoclave and related equipment |

Maintenance tips for ALC panel machinery to ensure longevity

Proper maintenance is crucial for maximizing the lifespan and efficiency of your equipment:

Daily Maintenance Routines

Implement these practices to keep your machines running smoothly:

- Regular lubrication of moving parts

- Cleaning of mixing blades and containers

- Inspection of hydraulic systems

- Checking electrical connections

Scheduled Maintenance Procedures

Follow this maintenance schedule for optimal performance:

| Time Interval | Maintenance Task | Expected Duration |

|---|---|---|

| Weekly | Belt tension checks | 1-2 hours |

| Monthly | Full system diagnostics | 4-6 hours |

| Quarterly | Major component inspection | 1-2 days |

Cost analysis of ALC panel manufacturing equipment

Understanding the financial aspects of ALC panel production is essential for business planning:

Initial Investment Breakdown

The startup costs typically include:

- Machine purchase (40-60% of total investment)

- Factory setup and infrastructure (20-30%)

- Raw material inventory (10-15%)

- Training and certification (5-10%)

Operational Cost Factors

Ongoing expenses to consider:

| Cost Category | Percentage of Total | Management Tips |

|---|---|---|

| Energy Consumption | 25-35% | Optimize autoclave cycles |

| Labor | 20-30% | Cross-train operators |

| Maintenance | 10-15% | Preventive maintenance program |

Future trends in ALC panel technology advancements

The ALC panel industry continues to evolve with new technological developments:

Innovations in Machine Design

Emerging trends include:

- Increased automation and IoT integration

- Energy-efficient autoclaving systems

- Advanced cutting precision technologies

- Improved material formulations

Sustainability Improvements

Environmental considerations are driving changes:

| Innovation Area | Environmental Benefit | Implementation Status |

|---|---|---|

| Waste Recycling | Reduces landfill by 90% | Pilot projects |

| Low-Carbon Production | 30% less CO2 emissions | Commercial availability |

| Water Conservation | 50% less water usage | Under development |