The AAC block production line is an essential component in the manufacturing of Autoclaved Aerated Concrete (AAC) blocks, a material known for its lightweight, durability, and eco-friendly characteristics. This production process is typically divided into several stages, with batching, pouring, and curing being crucial parts that directly influence the quality, consistency, and performance of the final product.

The Batching Section

Batching is the step in the AAC block production process. It involves the precise measurement and mixing of raw materials to create a uniform mixture suitable for pouring. The main materials used in this process are cement, lime, silica sand, water, and aluminum powder (or paste). The proportion of these materials is critical, as it determines the density, strength, and other physical properties of the final AAC block.

Key Functions of the Batching Section:

- Material Proportioning: Accurate proportioning ensures that the final mixture has the right consistency and quality.

- Consistency and Quality Control: The batching process guarantees that the mixture remains homogeneous, preventing inconsistencies in the final product.

- Material Handling: Proper storage and handling of raw materials prevent contamination, which could affect the overall performance of the AAC blocks.

Batching Equipment in an AAC Block Production Line:

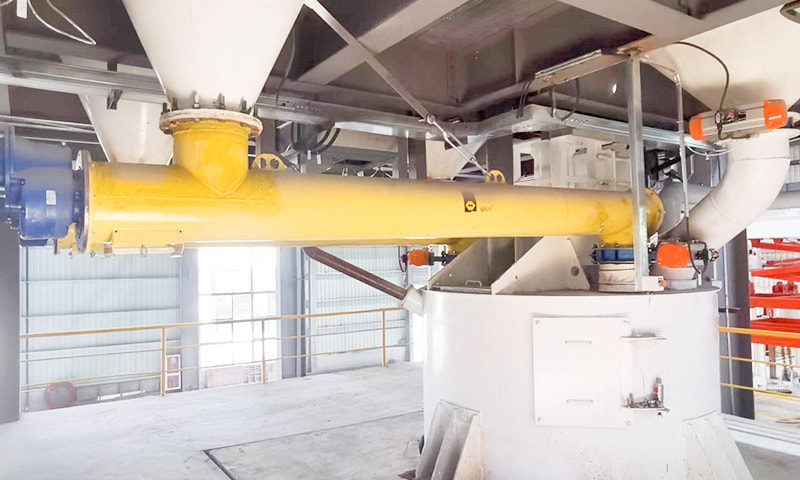

- Batch Mixers: These machines combine the raw materials according to the set proportions and ensure a uniform blend.

- Weighing Systems: Precise electronic weighing systems ensure that each material is measured accurately.

- Storage Silos and Bins: These systems store raw materials like sand, lime, and cement before they are batched.

Common Challenges in the Batching Process:

- Inaccurate material measurements can defects in the final blocks.

- Contamination of raw materials during handling can affect the quality of the AAC blocks.

The Pouring Section

Once the raw materials are mixed, the next step is pouring the mixture into molds. The pouring process is crucial as it determines the shape, size, and uniformity of the AAC blocks.

Key Functions of the Pouring Section:

- Mold Filling: The mixture is poured into pre-prepared molds, forming blocks of various sizes and shapes.

- Aluminum Paste Addition: Aluminum powder or paste is added during the pouring process to initiate the chemical reaction that generates air bubbles, giving the blocks their lightweight properties.

- Vibration: After the mixture is poured into the molds, vibration is applied to remove air pockets and ensure the mixture fills the mold uniformly.

Pouring Equipment in an AAC Block Production Line:

- Automatic Pouring Machines: These machines ensure that the correct amount of mixture is poured into each mold without spills or waste.

- Vibration Tables: These are used to shake the molds and ensure that the mixture is evenly distributed and compacted.

Challenges in the Pouring Process:

- Uneven pouring can result in inconsistent block sizes or uneven air pockets.

- Poor vibration can air pockets and reduced block strength.

The Curing Section

After the pouring section, the next step is curing, which is a vital process in ensuring the strength and durability of the AAC blocks. The curing process is typically carried out in an autoclave or a curing chamber, depending on the production method used.

Key Functions of the Curing Section:

- Heat and Pressure Application: In autoclaving, the poured AAC blocks are exposed to high temperatures (typically around 180°C to 200°C) and pressure. This helps in setting the chemical reaction initiated by the aluminum paste, which causes the blocks to harden and gain strength.

- Drying: Curing also helps in drying the blocks, removing excess water, and ensuring that the blocks can withstand the environmental conditions they will be exposed to.

- Accelerating the Hardening Process: Curing accelerates the hardening of the blocks, reducing the time needed for them to achieve full strength.

Curing Equipment in an AAC Block Production Line:

- Autoclaves: Large pressure vessels used to apply high heat and pressure to the blocks, speeding up the hardening process.

- Curing Chambers: These are used in some non-autoclave methods to create an environment where the blocks can cure at a controlled temperature and humidity.

- Curing Trolleys and Tracks: These help in moving blocks through the curing section, ensuring that they are placed in the correct environment for hardening.

Challenges in the Curing Process:

- Inadequate curing can result in weak AAC blocks, which may cause issues with strength and durability.

- Over-curing or curing at incorrect temperatures can cause block deformation or cracking.

Conclusion

The batching, pouring, and curing sections are integral to the AAC block production line, each playing a specific role in ensuring that the final product meets the required specifications for strength, durability, and other performance criteria. The quality of AAC blocks is highly dependent on how well these sections are managed and operated within the production line.

Efficient control over these processes leads to the production of high-quality AAC blocks, improving both the performance of construction projects and the overall cost-effectiveness of the AAC block production line factory.

FAQ

1. What is the role of the batching section in the AAC block production line?

The batching section ensures the precise measurement and mixing of raw materials, which is crucial for producing consistent and high-quality AAC blocks.

2. How does the pouring process affect the quality of AAC blocks?

The pouring process is essential for shaping the blocks and ensuring the correct mixture of raw materials. Proper pouring ensures uniformity and eliminates air pockets, which affects the block’s strength.

3. Why is the curing process critical in the AAC block production line?

Curing is vital because it accelerates the hardening process, strengthens the blocks, and ensures they are ready for use in construction.

4. What equipment is commonly used in the batching, pouring, and curing sections?

Common equipment includes batch mixers, automatic pouring machines, vibration tables, autoclaves, and curing chambers.

5. What challenges can arise in the batching, pouring, and curing sections?

Challenges include inaccurate material proportions, uneven pouring, and improper curing conditions, all of which can defects in the final AAC blocks.