Introduction to AAC Block Production

What are AAC blocks?

Autoclaved Aerated Concrete (AAC) blocks are a lightweight, precast building material that has been used in construction for many years. Invented in the 1920s in Sweden, AAC is a mix of cement, lime, silica sand, gypsum, and water, with a small amount of aluminum powder added as a foaming agent. This mixture is poured into molds, where a chemical reaction between the aluminum and the other components causes the material to expand and form a cellular structure with millions of tiny, air-filled pores. This process gives AAC its distinct lightweight and insulating properties. The “autoclaved” part of the name refers to the high-pressure steam curing process the blocks undergo, which gives them their final strength and durability.

Advantages of using AAC blocks in construction

AAC blocks offer a number of significant advantages over traditional building materials like fired clay bricks and concrete blocks.

Lightweight: Their low density makes AAC blocks easy to handle and transport, reducing labor costs and making construction faster. This also reduces the structural load on a building’s foundation, which can cost savings in the overall construction project.

Thermal Insulation: The porous, air-filled structure of AAC provides thermal insulation. This helps to maintain a stable indoor temperature, reducing the need for heating and cooling, which leads to lower energy consumption and costs.

Fire Resistance: AAC blocks are non-combustible and can withstand high temperatures, providing a high level of fire resistance. This enhances the safety of buildings constructed with AAC.

Sound Insulation: The cellular structure also provides good sound absorption, making AAC effective for acoustic insulation and helping to reduce noise transmission.

Eco-Friendly: The production of AAC blocks uses less energy than that of traditional fired bricks. Additionally, they are made from readily available, non-toxic raw materials and can be recycled. The energy efficiency of buildings made with AAC also contributes to a lower carbon footprint.

Durability and Pest Resistance: AAC blocks are resistant to termites and other pests, as well as rot and mold, ensuring a long lifespan for the structure.

Market demand and growth potential for AAC blocks

The global market for AAC blocks has been experiencing steady growth, driven by several factors. The increasing focus on green building and sustainable construction practices has boosted the demand for eco-friendly materials like AAC. Additionally, the growing need for affordable and efficient housing in developing economies, combined with a rising awareness of the energy-saving benefits of AAC, has further fueled market expansion. The versatility and ease of use of AAC blocks make them suitable for a wide range of applications, from residential and commercial buildings to industrial structures, which contributes to their strong market potential.

Setting Up an AAC Block Production Line

Raw Materials: Types and quality requirements

The core of AAC block production lies in the precise combination of its raw materials. The quality and proportion of each ingredient directly impact the final product’s strength, density, and thermal properties.

Silica: This is the main component, providing the bulk of the material’s solid structure. It is typically sourced from high-quality silica sand, fly ash (a byproduct of coal power plants), or ground slag. The silica content should be high, and the material should be finely ground to ensure a smooth, consistent mixture.

Cement: Ordinary Portland Cement (OPC) or a similar high-quality cement is used as the primary binder. It provides the initial strength to the mixture before autoclaving and contributes to the final structural integrity of the blocks.

Lime: Hydrated lime (calcium hydroxide) reacts with the silica to form calcium silicate hydrates during the autoclaving process. This reaction is what gives AAC its long-term strength and stability. The lime used must be of high purity.

Gypsum: A small amount of gypsum is added to control the setting time of the slurry and to promote the formation of the necessary crystalline structure during curing.

Aluminum Powder: This is the key leavening or foaming agent. When mixed with the other components, it reacts with the alkaline elements (cement and lime) to produce hydrogen gas. This gas forms millions of tiny bubbles throughout the slurry, creating the characteristic aerated structure of the AAC block. The fineness and quality of the aluminum powder are crucial for a consistent aeration process.

Manufacturing Process: Detailed steps from mixing to curing

The production of AAC blocks is a continuous, highly controlled process that can be broken down into several main stages.

Raw Material Preparation: All solid raw materials, such as silica, cement, and lime, are stored in silos. The silica (sand or fly ash) is ground into a fine powder in a ball mill to increase its reactivity.

Slurry Mixing: The prepared raw materials are accurately weighed and transported to a mixer. Water is added, and the ingredients are thoroughly mixed to create a homogeneous slurry. The precise ratio of each component is controlled by an automated batching system to ensure consistency.

Pouring and Aeration: The mixed slurry is poured into large steel molds. A small amount of aluminum powder is then added, which immediately starts the chemical reaction. The hydrogen gas produced causes the slurry to rise, much like dough, to fill the mold. This process, known as “pre-curing,” typically takes a few hours.

Cutting: Once the mixture has solidified into a “cake” that is firm enough to handle but still soft enough to cut, it is carefully lifted from the mold. Using a specialized cutting machine, the large cake is precision-cut into the desired block sizes. This cutting can be done with steel wires or a combination of saws, ensuring smooth surfaces and accurate dimensions.

Autoclaving (High-Pressure Steam Curing): The cut blocks are loaded onto trolleys and moved into large autoclaves, which are essentially industrial pressure cookers. Inside the autoclave, the blocks are subjected to high-pressure saturated steam (typically at temperatures around 190°C and pressures of 12-13 bar). This high-pressure curing process accelerates the chemical reactions, giving the AAC blocks their final, stable crystalline structure and exceptional strength.

Separation and Packaging: After the autoclaving process is complete, the blocks are removed, separated from the trolleys, and inspected for quality. They are then stacked on pallets, often shrink-wrapped, and prepared for transportation.

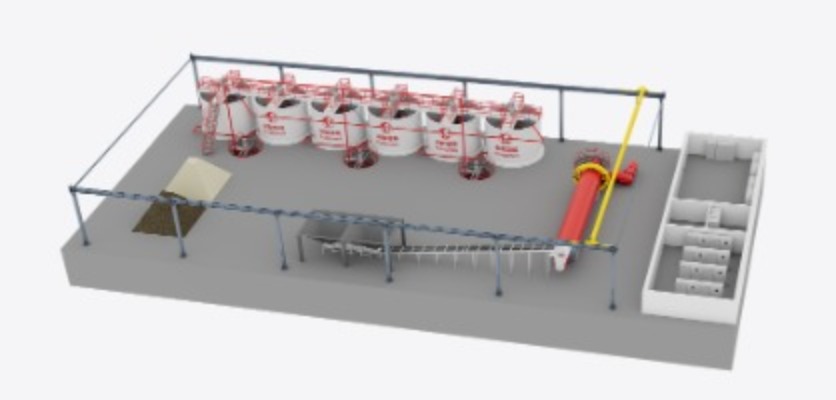

Equipment: Overview of essential machinery

A modern AAC block production line relies on a range of specialized machinery to automate and optimize each stage of the process.

Mixing and Batching System: This includes silos for storing raw materials, scales for precise weighing, and a large-capacity mixer for creating the slurry.

Cutting Machine: A machine for cutting the large AAC cake into individual blocks with high accuracy.

Molding System: Steel molds for casting the slurry and a handling system for moving the molds and the solidified cake.

Autoclave: The core of the factory, a massive pressure vessel where the high-pressure steam curing takes place.

Material Handling Equipment: Overhead cranes, transfer cars, and trolleys are essential for moving the heavy molds and blocks between different stages of the production.

Essential Equipment for AAC Block Production

Mixing and Batching System

This system is the starting point of the production process, where precision is paramount. It consists of multiple silos for storing bulk raw materials like silica, cement, and lime. . Automated scales and a conveyor system weigh and transport each component in exact proportions to the mixer. The mixer then combines the solid materials with water and other additives to create a homogeneous, uniform slurry. Advanced systems use computer control to ensure the correct recipe is followed for every batch, which is vital for product consistency.

Cutting Machine: Precision and automation

After the initial pre-curing, the large “cake” of aerated concrete needs to be cut into marketable block sizes. The cutting machine is responsible for this critical step. Modern cutting machines use a system of oscillating steel wires or specialized saws to slice the cake with high precision. They can be programmed to cut blocks of various dimensions, including different lengths, widths, and thicknesses, simultaneously. The automation in this stage minimizes waste and ensures that every block meets exact size specifications, which is essential for construction efficiency and reducing on-site labor.

Molding Machine: Different types and capacities

The molds are where the initial aeration and shaping of the AAC mixture occur. They are typically large, rectangular steel frames. The molding machine’s role is to fill these molds with the freshly mixed slurry. Depending on the factory’s capacity, these can be manual or fully automated systems that efficiently pour and transfer the molds to the pre-curing area. The molds are designed for quick demolding once the cake has reached the right consistency for cutting.

Autoclave: Importance and specifications

The autoclave is arguably the important piece of equipment in the entire process. . It’s a massive, cylindrical pressure vessel where the final curing and strengthening of the AAC blocks take place. The blocks are subjected to high-pressure saturated steam at temperatures of around 190°C. This environment triggers a final chemical reaction, converting the raw ingredients into a stable, durable material with its characteristic low density and high strength. Autoclave specifications, such as size and operating pressure, determine the factory’s production volume and the quality of the final product.

Cranes and Material Handling Equipment

Given the weight of the molds and the large volume of blocks being processed, a robust material handling system is crucial for efficient operation. This typically includes:

Overhead cranes to lift and move the large molds.

Transfer cars to transport trolleys loaded with blocks from the cutting area into the autoclaves.

Forklifts or automated stackers for moving the finished, palletized blocks to storage or shipping areas.

Boiler: Steam for curing

A high-capacity boiler is an essential component of the autoclaving system. It is responsible for generating the high-pressure steam required for the curing process. The boiler’s efficiency directly impacts the factory’s energy consumption and operational costs. Proper insulation and a well-maintained boiler system are key to optimizing this energy-intensive part of the production line.

AAC Block Production Line: Step-by-Step Guide

The manufacturing of AAC blocks is a fascinating process that combines chemistry, engineering, and automation. A modern production line orchestrates these elements into a seamless flow, from raw material to finished product.

Raw Material Preparation

Mixing and Pouring

Pre-Curing

Cutting

Autoclaving

Separation and Packaging

Cost Analysis of AAC Block Production

Initial Investment: Land, machinery, and construction

The initial investment for setting up an AAC block production line factory is substantial and includes several key components:

Land Acquisition: The size of the land required depends on the factory’s planned production capacity. A larger capacity will require more space for raw material storage, production facilities, finished goods storage, and administrative buildings.

Factory Construction: This includes the cost of building the main factory shed, warehouses for raw materials and finished products, a boiler room, a power substation, and an administrative block.

Machinery and Equipment: This is the significant portion of the initial investment. The cost varies widely based on the desired production capacity and the level of automation. A fully automated, high-capacity line will be considerably more expensive than a semi-automated, lower-capacity line. The cost includes all the essential equipment, such as the batching system, ball mill, mixer, molds, cutting machine, autoclaves, boilers, and material handling systems.

Installation and Commissioning: The cost of installing all the machinery and commissioning the plant to ensure it is operating correctly and efficiently. This can also include training for the operating staff.

Contingency Fund: It is wise to set aside a portion of the budget (typically 10-15%) for unforeseen costs.

Operational Costs: Raw materials, labor, energy, and maintenance

Once the factory is up and running, a separate set of recurring costs must be managed for profitability:

Raw Materials: This is a major ongoing expense. The cost of raw materials—silica (sand or fly ash), cement, lime, gypsum, and aluminum powder—is subject to market fluctuations. Securing reliable and cost-effective suppliers is vital.

Labor: The cost of hiring and retaining a skilled workforce, including engineers, machine operators, technicians, and administrative staff. A more automated production line may require fewer laborers but more highly skilled technical personnel.

Energy: AAC production is an energy-intensive process. The primary energy costs come from the electricity required to run the various machines (mills, cutters, conveyors) and the fuel (coal, natural gas, or oil) needed for the boiler to produce steam for the autoclaves.

Maintenance: Regular maintenance of all machinery is essential to prevent breakdowns and ensure long-term efficiency. This includes both routine servicing and the cost of replacing worn-out parts.

Utilities and Overheads: Other operational costs include water, taxes, insurance, and administrative expenses.

ROI and Profitability: Factors affecting profitability

The return on investment (ROI) and overall profitability of an AAC block production line are influenced by a number of factors:

Production Efficiency: Maximizing output while minimizing waste is key. A well-designed production line with a high level of automation and reliable equipment will have a higher production efficiency.

Market Price: The selling price of AAC blocks is determined by regional market demand, competition, and the cost of alternative building materials.

Raw Material Costs: Efficient supply chain management and the ability to source materials at a competitive price can significantly impact the bottom line.

Energy Management: Implementing energy-saving technologies and practices can help reduce one of the biggest operational expenses.

Product Quality: Producing high-quality blocks that consistently meet industry standards can command a better price and build a strong brand reputation.

Key Considerations for Choosing an AAC Block Production Line

Capacity: Matching production to market demand

Automation Level: Balancing cost and efficiency

Technolog: Latest advancements in AAC block production

Supplier Reputation: Choosing reliable equipment manufacturers

Quality Control in AAC Block Manufacturing

| Quality Control Stage | Key Tests / Points | Purpose / Focus | Common Issues & Prevention |

|---|---|---|---|

| Raw Material Inspection | Fineness of silica sand, purity of lime, quality of cement | Ensure raw materials meet specifications | Substandard materials can cause uneven strength or density, affecting final product quality |

| Dimensional Accuracy | Measure length, width, height (±1.5 mm) | Ensure proper fit in construction and reduce mortar usage | Poorly calibrated cutting machines or uneven “green cake” expansion |

| Compressive Strength | Test load-bearing capacity in a compression machine | Ensure safety for load-bearing or non-load-bearing walls | Incorrect raw material ratios or unstable autoclaving conditions |

| Dry Density | Typically 400–800 kg/m³ | Evaluate lightweight and insulation properties | Inconsistent mix ratios or uneven autoclave temperature/pressure |

| Thermal Conductivity | Measure heat transfer resistance | Assess insulation performance | Material inconsistencies or improper autoclaving |

| Drying Shrinkage | Measure shrinkage after drying | Prevent wall cracking | Improper mix, cutting, or curing |

| Water Absorption | Measure water uptake | Ensure performance and durability | High absorption reduces long-term durability |

| Finished Product Testing | Sample testing of all key properties per batch | Record data and analyze trends | Neglecting testing may delay defect detection |

Conclusion

The AAC block industry is on a path of continuous innovation, driven by the global push for sustainability, increasing demand for affordable housing, and rapid technological advancements. These trends are reshaping how AAC blocks are produced and used, promising a more efficient and eco-friendly future for the construction sector.

Technological Advancements: Automation and AI

Advanced Automation and Robotics: While automation is already a key feature of modern AAC plants, the next generation will see more sophisticated robotics. Robots will perform a wider range of tasks, from precise material handling and stacking to complex packaging and quality inspection. This reduces human error, increases production speed, and enhances safety.

AI-driven Quality Control: AI and machine learning will revolutionize quality control. . AI-powered systems with high-resolution cameras and sensors will be able to instantly detect even the slightest defects on blocks as they move down the production line. This allows for real-time adjustments to the process, ensuring consistent quality and minimizing waste.

Predictive Maintenance: Instead of following a fixed maintenance schedule, AI and data analytics will enable predictive maintenance. Sensors on equipment will monitor performance and predict when a component is likely to fail, allowing for proactive maintenance before a costly breakdown occurs.

Sustainable Practices: Innovations in eco-friendly production

Waste Material as Raw Material: Research is ongoing to increase the use of recycled materials and industrial byproducts. The use of fly ash is already common, but future innovations may include incorporating other waste streams like crushed glass or certain types of plastic to create hybrid materials that are both eco-friendly and high-performing.

Lower Energy Consumption: Future plants will focus on optimizing energy use, especially in the energy-intensive autoclaving process. Innovations in boiler technology and waste heat recovery systems will be critical in reducing a factory’s overall energy demand.

Carbon Neutral Production: The ultimate goal for the industry is to achieve carbon-neutral production. This could involve using renewable energy sources to power the plant, sequestering carbon emissions, and developing new recipes that use lower-carbon binders.