With the growth of demand for lightweight, high-strength and environmentally friendly materials in the construction industry, the importance of AAC block plant in the market continues to increase. Especially after the introduction of the automated production line, AAC block plant has shown significant advantages in production efficiency, cost control and product quality, becoming the key to building materials manufacturers to improve their competitiveness.

Improve production efficiency

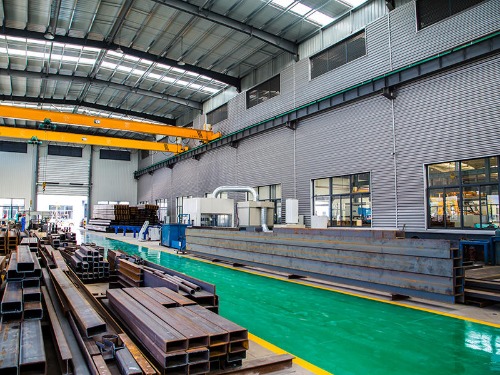

Automated production lines are an important milestone in the development of AAC block plant. By adopting modern equipment and intelligent control systems, the entire production process is almost fully automated from raw material mixing, mold filling to cutting and maintenance.

This efficient process greatly shortens the production cycle and avoids uncertainty and inefficiency in manual operations. Intelligent operations can also adjust production parameters according to order demand, thereby meeting the market's demand for diversified products.

Reduce production costs

The automation system of AAC block plant also performs outstandingly in cost savings. On the one hand, automation equipment reduces dependence on labor and significantly reduces labor costs; on the other hand, automated production can more accurately control the proportion of raw materials use, avoiding waste of raw materials. In addition, energy efficiency optimization technology also significantly reduces energy consumption, thereby further reducing the overall production cost.

Improve product quality

The automated production line can accurately control the process parameters of each link, thereby improving product quality consistency. For example, cutting equipment can ensure the precise dimensions of each AAC block, while automated maintenance systems ensure that the material hardens under ideal conditions, improving product strength and durability. This high-quality product not only meets industry standards, but also meets the market's demand for high-quality building materials.

Enhance market competitiveness

Through automated production lines, AAC block plant far exceeds traditional factories in production scale and efficiency, thus bringing stronger market competitiveness to the company. Rapid response to orders, delivering high-quality products and reducing production costs have made these factories dominate the building materials market.

The introduction of automated production lines enables AAC block plant to achieve comprehensive breakthroughs in efficient production, cost control and product quality improvement. This technological innovation not only promotes the development of the building materials production industry, but also provides better solutions for green buildings and sustainable development. In the future, automated production lines will continue to lead the AAC block plant to develop in the direction of intelligence and environmental protection, creating more value for the construction industry.