Introduction to AAC Blocks

What are AAC Blocks?

Autoclaved Aerated Concrete (AAC) is a lightweight, precast, and versatile building material used for construction. Composed primarily of sand, cement, lime, water, and a small amount of aluminum powder, AAC blocks have gained popularity due to their numerous advantages, such as thermal insulation, fire resistance, and reduced environmental impact. The process of making AAC involves a highly controlled reaction between these ingredients that results in a porous material.

Brief History and Development of AAC Technology

The technology behind AAC was developed in Sweden in the early 20th century by Dr. Johan Axel Eriksson, who invented the process of autoclaving concrete. Since then, AAC has grown to become a widely used material in residential, commercial, and industrial construction due to its durability, cost-effectiveness, and eco-friendly properties. The advent of modern AAC block manufacturing technologies has significantly improved production efficiency and material quality, making AAC blocks a go-to option for modern construction.

Advantages of Using AAC Blocks

AAC blocks provide numerous benefits that make them stand out as a preferred choice in the building materials industry.

Lightweight Properties and Their Benefits

The notable feature of AAC blocks is their lightweight nature, making them easier to handle, transport, and install. This reduces labor costs and the need for heavy equipment during construction. Additionally, the reduced weight of AAC blocks decreases the overall structural load, which can be crucial in high-rise buildings and areas with weak soil.

Excellent Thermal Insulation for Energy Efficiency

AAC blocks have thermal insulation properties due to their porous structure. They significantly reduce heat transfer, ensuring that buildings remain cool in the summer and warm in the winter. This can substantial savings on energy bills, contributing to a more sustainable and energy-efficient construction.

Superior Fire Resistance Compared to Traditional Materials

The fire-resistant properties of AAC blocks are unmatched in the construction industry. Their inherent non-combustibility, combined with their ability to withstand high temperatures, makes them an ideal choice for fireproofing. This feature adds an additional layer of safety to buildings, reducing the risk of fire-related damage.

Acoustic Performance and Sound Insulation

AAC blocks are also known for their sound insulation properties. The porous nature of the material absorbs sound, making AAC blocks ideal for use in noise-sensitive environments, such as residential apartments, offices, and hospitals. Their acoustic performance ensures a peaceful living or working environment, free from external noise disturbances.

Eco-Friendliness and Sustainability Aspects

As the demand for sustainable building materials grows, AAC blocks stand out for their minimal environmental impact. The production process consumes less energy than traditional concrete, and the materials used are recyclable and sourced from abundant natural resources. Moreover, AAC blocks are free from harmful chemicals and contribute to the construction of green buildings.

The AAC Block Production Line: A Step-by-Step Guide

The production of AAC blocks involves several key steps, each of which is critical to ensuring the quality and efficiency of the final product. The process is automated, reducing labor costs and improving consistency.

Raw Materials and Their Preparation

Cement: Type and Quality Requirements

Cement is the primary binding agent in the AAC production process. The quality of cement plays a crucial role in ensuring the strength and durability of the blocks. High-quality Portland cement is typically used, which provides bonding properties during the manufacturing process.

Lime: Importance of High-Quality Lime

Lime is another essential component in AAC block production. It reacts with the silica in the sand to form calcium silicate, contributing to the strength of the final product. Using high-quality lime ensures a better reaction and a more stable final product.

Silica Sand or Fly Ash: As a Primary Component

Silica sand or fly ash serves as the primary source of silica, which is vital for the formation of calcium silicate during the reaction process. Fly ash, a byproduct of coal combustion, is increasingly being used due to its cost-effectiveness and eco-friendly nature.

Gypsum: Role in the Reaction Process

Gypsum regulates the setting time of the mixture, ensuring that the AAC blocks cure correctly. The addition of gypsum helps in controlling the speed of the chemical reactions during production.

Aluminum Powder: Function as an Expansion Agent

Aluminum powder is used as an expansion agent. When mixed with the other ingredients, it reacts with the lime to release hydrogen gas, creating the porous structure that makes AAC blocks lightweight and insulating.

Water: Quality and Quantity Considerations

Water is used to activate the chemical reactions between the ingredients. The quality of water is crucial, as it affects the consistency of the mixture and, ultimately, the quality of the AAC blocks.

Mixing and Pouring

The raw materials are mixed in a controlled environment to form a slurry. Automated batching and mixing systems ensure consistency in the mixture, while slurry preparation systems monitor the consistency and quality of the mixture. Once the mixture is ready, it is poured into molds to form the desired shape and size of the AAC blocks.

Pre-Curing

Pre-curing takes place in a controlled environment, where temperature and humidity levels are carefully monitored to ensure that the mixture sets correctly before undergoing autoclaving. This step is crucial to ensure proper chemical reactions take place and the blocks maintain their integrity.

Cutting

Once the blocks have set, they are cut into the desired dimensions using automated cutting machines. Precision cutting technologies, such as wire cutting and band saw cutting, ensure that each block is uniform and meets the required standards. Any waste generated during cutting is recycled to minimize material loss.

Autoclaving

Autoclaving is a high-pressure steam curing process that enhances the strength and durability of AAC blocks. During this process, the blocks are exposed to high temperatures and pressure within an autoclave, which triggers chemical reactions that solidify the material. The control of temperature and pressure during this process is crucial to achieving the desired properties of the AAC blocks.

Separation and Packaging

After autoclaving, the blocks are separated, inspected for quality, and sorted into different grades based on their size and quality. They are then packaged for transportation and storage, ensuring they are protected from environmental factors that could affect their quality.

Key Machinery and Equipment

An AAC block production line requires various types of machinery, each designed for a specific function.

| Equipment | Function |

|---|---|

| Mixing System | Automated batching and slurry mixing |

| Molding Equipment | Molding AAC blocks into desired shapes |

| Cutting Machines | Precision cutting of blocks to required sizes |

| Autoclave | High-pressure curing of blocks for enhanced strength |

| Material Handling Equipment | Conveyors, cranes, and forklifts for efficient material flow |

Mixing System

The mixing system consists of high-capacity mixers capable of handling large batches of raw materials. These mixers ensure uniformity and consistency in the slurry, which is essential for producing high-quality AAC blocks.

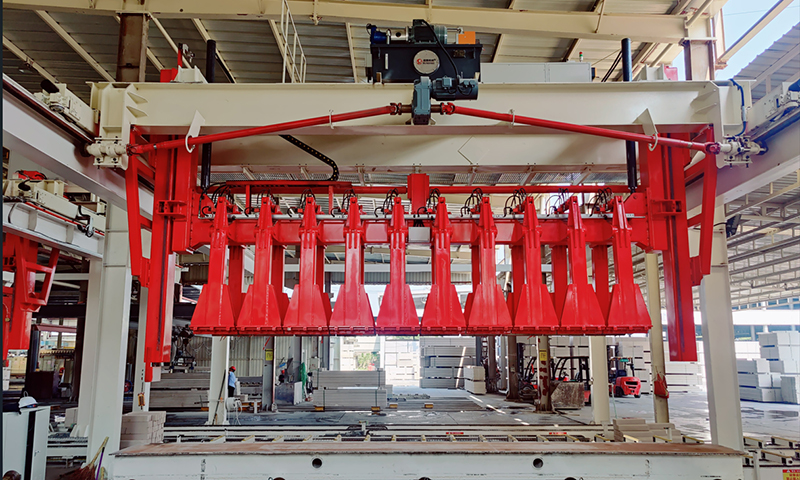

Molding Equipment

Molding equipment includes molds of various sizes and shapes to accommodate different types of AAC blocks. Automated mold handling systems help reduce manual labor and improve production efficiency.

Cutting Machines

Cutting machines, such as wire cutters and band saws, are used to cut the set blocks into precise dimensions. The choice of cutting method depends on the specific requirements of the production line and the type of AAC block being produced.

Autoclave

Autoclaves are critical to the curing process, as they ensure that AAC blocks achieve the required strength and durability. There are two primary types of autoclaves used: horizontal and vertical, each with its own advantages in terms of capacity and efficiency.

Setting Up an AAC Block Production Line

Site Selection and Layout

The site for an AAC block production line must be chosen carefully, considering factors such as proximity to raw materials, transportation infrastructure, and environmental regulations. The layout of the plant should be optimized for efficiency, with clear flow paths for materials and finished products.

Infrastructure Requirements

An AAC block production line requires a reliable power supply, water treatment systems, and waste management facilities. These infrastructure requirements must be planned carefully to ensure smooth and continuous production.

Regulatory Compliance and Permits

Compliance with local building codes, environmental regulations, and safety standards is essential when setting up an AAC block production line. Obtaining the necessary permits and approvals ensures that the plant operates legally and safely.

Cost Analysis of AAC Block Production

Initial Investment

Setting up an AAC block production line requires significant initial investment. Costs include land acquisition, machinery, equipment, and infrastructure development. However, the long-term savings in labor and material costs, as well as the ability to meet growing demand for sustainable building materials, make it a worthwhile investment.

Operating Costs

The operating costs of an AAC block production line include raw material costs, energy consumption, labor expenses, and maintenance. Effective management of these costs is key to ensuring profitability.

Return on Investment (ROI)

The ROI for an AAC block production line depends on market demand, production capacity, and efficiency. A well-designed production line can yield a high ROI, particularly with the growing demand for sustainable building materials.

Conclusion

In conclusion, the AAC block production line offers a highly efficient and cost-effective method of producing lightweight, durable, and eco-friendly building materials. The key advantages of AAC blocks, including their thermal insulation, fire resistance, and acoustic properties, make them a popular choice in modern construction.

FAQ

1. What are the benefits of using AAC blocks in construction?

AAC blocks offer lightweight properties, thermal insulation, fire resistance, and sound insulation, making them ideal for a wide range of construction applications.

2. How is an AAC block production line set up?

An AAC block production line requires careful site selection, infrastructure development, and compliance with local regulations. Key machinery includes mixing systems, molds, cutting machines, and autoclaves.

3. What are the raw materials used in AAC block manufacturing?

The primary raw materials include cement, lime, silica sand or fly ash, gypsum, aluminum powder, and water.

4. How does the autoclaving process work in AAC block production?

Autoclaving is a high-pressure steam curing process that solidifies the AAC blocks, enhancing their strength and durability. Temperature and pressure are carefully controlled to achieve results.