Request for a call today

AAC Block Production Line Suppliers

-

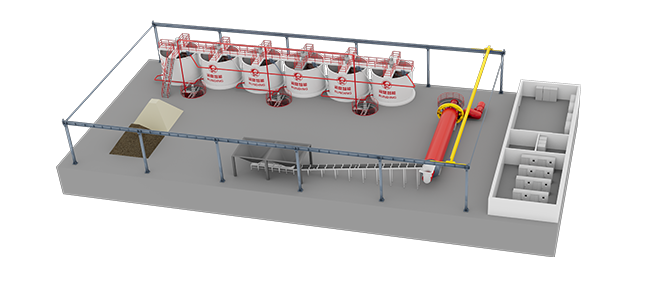

Slurry Preparation Section is a collection of key equipment focusing on material preparation and processing, and is widely used in industrial pulping and production processes. The equipment under this classification is mainly responsible for completing the crushing, grinding, conveying, storage and metering of materials, and providing homogeneous, efficient slurry and accurate material supply for subsequent processes. With high reliability and stability as the core, these equipment are suitable for handling a variety of types of raw materials, and show performance in high-strength operating environments. They are an important part of achieving industrial automation and process optimization.

-

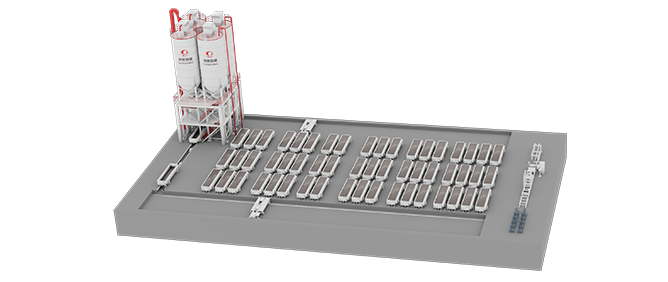

Batching, Pouring, Curing Section Service is a comprehensive solution focusing on the ingredients, pouring and maintenance phases during the production process. The equipment under this category supports accurate metering, diversified mixing and efficient casting operations, and provides mold and vehicle assistance to ensure the continuity and stability of the production process. These equipment are characterized by high precision, high automation and reliability, and can meet the production needs of different scales, optimize material utilization, and improve product quality. In addition, they play a key connection role in the production line, ensuring the smooth operation of the entire process and providing solid guarantees for efficient manufacturing and quality control.

-

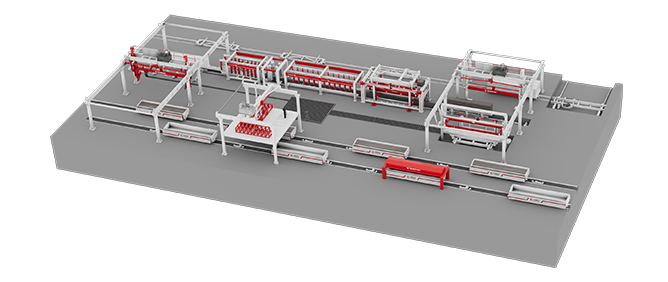

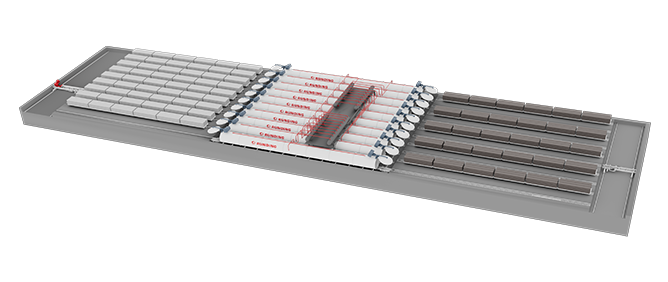

Tilting, Cutting Section is a core category of equipment that focuses on the flip and cutting links in industrial production. The equipment under this classification is mainly used for precise flipping, initial cutting, longitudinal cutting and transverse cutting of materials or molded parts to ensure the consistency of product size and stability of quality. These devices usually have high precision and high efficiency characteristics, adapt to a variety of process needs, and are outstanding in space utilization and operational flexibility. Through automated control and optimized design, this category of equipment can significantly improve production efficiency, reduce manual intervention, and ensure smooth connection and efficient operation of the production line.

-

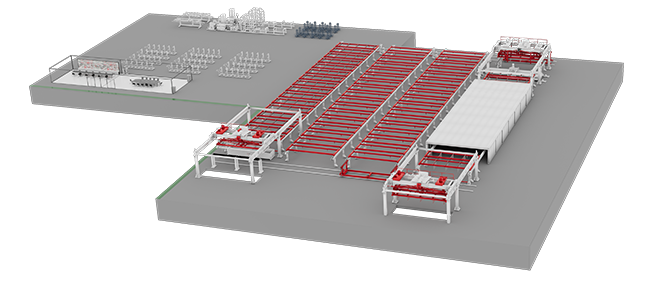

Grouping Before Autoclave Section covers a range of equipment dedicated to pre-autoclave product grouping and conveying. Through efficient grouping, lifting and transportation operations, these equipment arrange materials in an orderly manner and safely transport them to the autoclave process to ensure the efficiency and consistency of the overall process. They are characterized by precise operation mode and stable performance, adapt to the needs of different production scales, while reducing manual intervention and optimizing logistics efficiency. This type of equipment not only improves the automation level of the production line, but also provides strong guarantees for the efficient connection of the autoclave process and the stability of product quality.

-

Product Autoclaving Section is a key equipment category designed for the autoclaving process, covering the operational support from product entry to completion of autoclaving processing. These equipment coordinate the loading, conveying and unloading of materials, ensuring uniform pressing and heating under the autoclaving environment, and achieving product stabilization treatment. By optimizing operating efficiency and high-strength structural design, they can adapt to the needs of large-scale production while ensuring operational accuracy and safety. This classification equipment not only improves the automation level of the autoclave process, but also plays a core role in connecting the past and the future in the production process, helping to efficiently manufacture high-quality products.

-

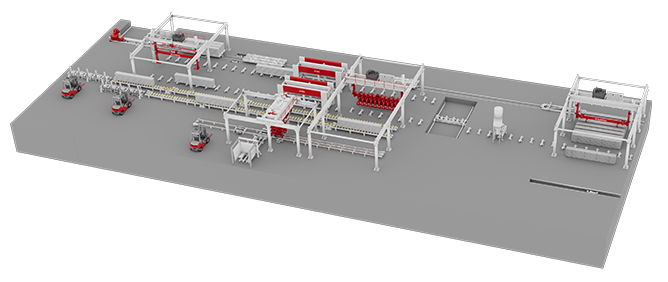

Packing Section is a category of equipment that focuses on product sorting, transportation and packaging preparation, covering multiple key links from unloading after autoclaving to before final packaging. These devices ensure that the product enters the packaging process in a standardized form through efficient transport, separation, combination and rotation operations. They feature flexible design and precise operation to adapt to product requirements of different specifications while optimizing process connection and space utilization. This type of equipment plays an important role in improving production line efficiency, ensuring product quality and shortening packaging cycles, providing efficient support for the overall production process.

-

Reinforcement Welding Section is a category of equipment that focuses on steel bar welding and related operations, covering multiple links of steel bar processing, conveying, assembly and protective treatment. These equipment ensures the strength and stability of the steel bar structure through high-precision welding and efficient transport, while meeting the design needs of different specifications and complexities. Its characteristics are high automation level of operation and strict control of welding quality, which is suitable for batch and standardized production environments. This type of equipment not only optimizes the steel bar processing process, but also has significant advantages in improving operational efficiency and product consistency, laying the foundation for the manufacturing of high-quality building components.

-

Pull&Insert Bar Section focuses on providing efficient and precise bar handling solutions for a wide range of industrial scenarios. The product design under this category is designed to simplify the insertion, pulling and maintenance of bars, improve operational efficiency and reduce manual intervention. These devices usually have high-strength structural designs that can withstand heavy loads and frequent operations, while focusing on safety and durability. Through automated or semi-automated features, they help users achieve smoother production processes and reduce equipment maintenance costs. Whether it is the cleaning, lifting or soaking bars, they can meet diverse industrial needs and are an indispensable part of modern production lines.

-

13+

Years Industry Experience

-

50000+

Factory Area

Jiangsu Runding founded in 2011, is Custom OEM OEM AAC Block Production Line Manufacturers, is an innovative intelligent technology company focusing on AAC block and AAC panel intelligent production line equipment and AAC products intelligent factory ecological chain construction.

The company is headquartered in Nandu Intelligent Equipment Industrial Park, Liyang City, Jiangsu Province, integrating research and development, production, sales and service. The company's innovative AAC production line intelligent equipment, intelligent factory management, AAC process formula and etc., serve many customers at domestic and overseas, we are Custom OEM AAC Block Production Line Suppliers, Factory,promote the technical innovation of the AAC industry, win the industry consensus recognition and good market reputation, and export China's intelligent manufacturing to the world.

Runding company firmly established the guiding position in the AAC production line intelligent equipment industry, Runding people focus on technology, quality and innovation, to ensure advanced equipment, stability and economy, providing customers with professional and satisfactory AAC intelligent products overall solution.

We sincerely look forward to visits and exchanges from all walks of life, and jointly contribute to the development of green building materials and the promotion of global carbon neutrality.

Industry Knowledge

What is the role of AAC block production line in shaping the future of green building materials?

The AAC block production line is more than just a simple production facility; it’s a fusion of materials science, intelligent equipment, and industrial automation. Its efficiency, stability, and innovation directly impact the global adoption of aerated concrete (AAC) blocks. AAC block production line manufacturers and individual AAC block production line factory play a central role in shaping the trajectory of the green building industry.

The Fundamentals of AAC block production line

AAC block production line is a highly integrated manufacturing system designed to produce AAC blocks through a sequence of precisely controlled processes. Unlike traditional brick-making facilities, this system is engineered to handle a continuous, automated workflow, ensuring consistency and quality.

Core stages include:

Raw material preparation: Lime, cement, gypsum, sand, or fly ash are measured and ground to required fineness.

Batching and mixing: Intelligent control systems deliver precise proportions, ensuring slurry homogeneity.

Pouring and pre-curing: The slurry is poured into molds, where gas expansion creates the block’s cellular structure during resting.

Cutting process: After demolding, green cakes are cut into exact dimensions by advanced cutting machines, ensuring minimal waste.

Autoclaving: High-pressure steam curing in autoclaves gives the blocks their strength, stability, and durability.

Packaging and dispatch: Finished blocks are automatically stacked and prepared for transportation.

Each step reflects the importance of precision and automation. The sophistication of equipment in every AAC block production line factory determines the final product’s performance in terms of density, strength, and thermal efficiency.

Industry Significance of AAC block production line

The strategic importance of AAC block production line manufacturers lies in their ability to meet construction demands while supporting environmental goals. These production systems deliver far more than capacity; they define standards for energy efficiency and sustainability.

Green material promotion: The production line ensures AAC blocks are manufactured at scale, supporting the replacement of traditional energy-intensive bricks.

Smart factory transformation: Advanced lines integrate automation, robotics, and IoT systems, enabling predictive maintenance and reduced labor dependency.

Global competitiveness: A high-quality production line provides reliable products for domestic and international markets, enhancing a factory’s reputation and profitability.

Technology Priorities of AAC block production line manufacturers

For AAC block production line manufacturers, innovation is not optional; it is the lifeline of competitiveness. The focus is primarily on four technological priorities:

Automation and intelligent monitoring – From PLC systems to SCADA platforms, smart monitoring ensures uninterrupted, optimized production.

Energy-saving solutions – Improved autoclaves and waste heat recovery systems cut down energy consumption.

Flexible production capabilities – Modern lines are designed to manufacture AAC products in diverse sizes and densities, adaptable to market demand.

Lifecycle support – Comprehensive services, from project design and installation to after-sales maintenance, provide long-term value for clients.

Industry Contribution

As an example of innovation-driven manufacturing, Jiangsu Runding Intelligent Equipment Technology Co., Ltd. has integrated research, production, sales, and service into one system. The company has established itself as a pioneer in developing intelligent AAC block production solutions.

Innovation and R&D: The company develops advanced equipment and proprietary AAC process formulations to ensure efficiency and stability.

Intelligent factory solutions: Its systems enable data-driven factory management, offering visualization and digitalization throughout the production cycle.

Quality and stability: Strict quality control ensures that equipment delivers consistent performance in long-term operations.

Global recognition: With clients across different regions, the company has earned a strong reputation and has become a representative of China’s intelligent manufacturing on the global stage.

Through these efforts, Jiangsu Runding has redefined what a modern AAC block production line factory should achieve—combining productivity, sustainability, and intelligence.

Green and Low-Carbon Value of AAC block production line

The sustainability of AAC blocks is inseparable from the equipment that manufactures them. A modern AAC block production line contributes to global carbon neutrality in several ways:

Energy efficiency: Optimized steam curing and heat recycling significantly lower energy intensity.

Waste utilization: Many lines are designed to use fly ash or industrial by-products, reducing landfill pressure.

Carbon footprint reduction: Widespread AAC adoption helps cut emissions from traditional building materials, supporting carbon neutrality goals.

Future Trends in AAC block production line Development

The evolution of the AAC industry is closely tied to equipment innovation. AAC block production line manufacturers will continue to explore several directions:

Higher automation: Robotics and AI-driven controls will minimize manual intervention.

Eco-friendly upgrades: Equipment will be further optimized to lower energy and water consumption.

Global customization: Production lines will be designed to meet diverse building codes and environmental standards worldwide.

Integrated solutions: Manufacturers will expand beyond equipment delivery, providing holistic services including intelligent plant layout and lifecycle management.